Abstract

The debate between quartz and granite for countertop applications is a perpetual one in the realms of interior design and construction. Both materials offer compelling aesthetic and functional benefits, yet their distinct compositions, manufacturing processes, and inherent properties lead to significant differences in performance, maintenance requirements, and suitability for various applications. This technical article provides an in-depth comparison of quartz (engineered stone) and granite (natural stone), dissecting their geological origins or manufacturing methods, physical and chemical characteristics, durability metrics, maintenance protocols, aesthetic versatility, and environmental impacts. By examining these factors from a scientific and practical perspective, we aim to equip consumers, designers, and contractors with the comprehensive knowledge necessary to make informed decisions tailored to specific project needs and long-term expectations.

1. Introduction: Natural Beauty vs. Engineered Innovation

For decades, granite reigned supreme as the quintessential high-end countertop material, celebrated for its unique natural patterns and robust durability. However, the emergence and rapid evolution of quartz countertops, an engineered stone product, have presented a formidable challenger, offering a compelling blend of aesthetics, performance, and consistency. The choice between these two popular options often boils down to a fundamental question: is natural always superior, or does human engineering offer advantages that supersede nature's artistry?

This article will move beyond anecdotal preferences to provide a technical comparison. We will explore the intrinsic properties of granite, formed over millennia deep within the Earth, versus the meticulously controlled manufacturing process of quartz. Understanding their respective strengths and weaknesses, from molecular structure to surface resilience, is crucial for anyone navigating the complex world of material selection for kitchens, bathrooms, and other demanding surfaces.

2. Composition and Formation/Manufacturing Process

The fundamental difference between quartz and granite lies in their origin.

2.1 Granite: Nature's Masterpiece

Granite is an igneous rock, formed from the slow crystallization of magma (molten rock) beneath the Earth's surface over millions of years. Its characteristic coarse-grained texture is a result of this slow cooling process, allowing large mineral crystals to form.

Composition: Geologically, true granite is primarily composed of:

Quartz (20-60%): A very hard mineral (7 on the Mohs scale of hardness).

Feldspar (up to 65-90% of total feldspar minerals): Provides much of granite's color and is also hard, though generally slightly less so than quartz.

Mica (3-10%): Contributes to the flecks and sparkle.

Minor minerals (e.g., amphibole, hornblende): Contribute to the unique coloration and patterns found in different slabs.

Formation: Deep within the Earth's crust, magma intrudes into existing rock. As it cools very slowly, minerals crystallize and interlock, forming a dense, durable rock.

Extraction: Granite is quarried from the Earth in large blocks using drilling, blasting, or wire-sawing techniques. These blocks are then transported to processing facilities where they are sliced into slabs of various thicknesses (typically 2 cm or 3 cm) using large diamond-tipped saws.

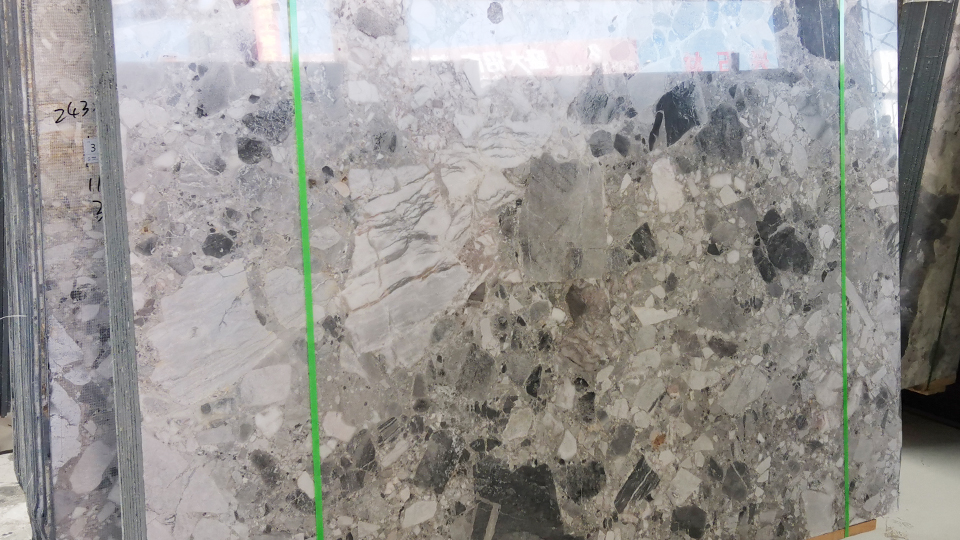

Unique Aesthetics: Because it's a natural product, every slab of granite is unique. Its patterns, veining, and color variations are entirely dependent on the specific geological conditions of its formation. This uniqueness is a major draw for many consumers.

2.2 Quartz: Engineered Precision

Quartz countertops, often referred to as "engineered stone," are a man-made product. They are manufactured through a highly controlled industrial process.

Composition: Quartz countertops are typically composed of:

Crushed Natural Quartz (90-95%): This is the primary aggregate, derived from natural quartz minerals, ground to various sizes (from fine sand to coarse颗粒) to achieve different textures and looks.

Polymer Resins (5-10%): These act as a binding agent, holding the quartz particles together. Polyester resins are most common, though acrylic resins are also used.

Pigments: Added to control the color and achieve a consistent hue or a specific aesthetic.

Other Materials (optional): Glass, metallic flecks, or mirror chips may be added for decorative effect.

Manufacturing Process (Vibro-compression/Bretonstone Technology):

Raw Material Preparation: Natural quartz is crushed and mixed with resins and pigments in precise proportions.

Molding: The mixture is poured into molds to form slabs of desired dimensions.

Vibro-compression: The filled molds are then placed into a vacuum chamber where they undergo vibro-compression (vibration under vacuum). This process removes air pockets, compacts the material, and ensures a dense, non-porous slab.

Curing: The compressed slabs are then cured (heated and hardened) in kilns, solidifying the resin binders and creating a strong, durable material.

Polishing and Finishing: After curing and cooling, the slabs are calibrated and polished using diamond abrasives to achieve the desired finish (e.g., polished, honed, leathered).

Consistent Aesthetics: Due to the controlled manufacturing process, quartz offers remarkable consistency in color and pattern across different slabs of the same design. This allows for seamless installations over large areas and predictable aesthetic outcomes.

3. Technical Characteristics and Performance Metrics

A direct comparison of key performance indicators reveals the inherent strengths and weaknesses of each material.

3.1 Hardness and Scratch Resistance

Granite: Ranges from 6−7 on the Mohs scale of hardness (due to its quartz and feldspar content). This makes it highly resistant to scratches from common kitchen implements. While durable, sharp knives can dull and repeated cutting directly on its surface can cause minor scratches or affect its sealant.

Quartz: Also ranks around 7 on the Mohs scale due to its high quartz content. The resin binder provides some flexibility, making it slightly more resistant to chipping than granite under impact. However, the resin itself can be scratched or marred by sharp objects if significant force is applied, and it can dull knives more quickly than granite.

3.2 Porosity and Stain Resistance

Granite: Is a porous natural stone. Its porosity varies depending on the specific type of granite and its mineral composition (e.g., lighter granites tend to be more porous). If unsealed or improperly sealed, liquids (wine, oil, coffee, acidic juices) can penetrate the surface and cause staining.

Quartz: Is non-porous due to the resin binders and the vibro-compression manufacturing process that eliminates microscopic pores. This makes quartz highly resistant to stains from common household liquids. It also means quartz does not harbor bacteria, mold, or mildew, contributing to a more hygienic surface.

3.3 Heat Resistance

Granite: Formed under extreme heat and pressure, granite is inherently highly heat-resistant. Hot pots and pans can generally be placed directly on its surface without immediate damage. However, extreme thermal shock (e.g., placing a very hot pan from the oven directly onto a very cold granite surface) can, in rare cases, cause cracking. Prolonged exposure to concentrated heat can also potentially affect the sealant.

Quartz: While the quartz mineral itself is heat-resistant, the resin binders are not. Polyester resins typically have a maximum temperature threshold (often around 150

∘

F or 65

∘

C). Prolonged exposure to temperatures above this threshold can cause the resin to scorch, discolor, or weaken, leading to permanent damage (e.g., yellowing, white marks, bubbling, or cracking). Trivets and hot pads are essential for quartz countertops.

3.4 Chemical Resistance

Granite: Generally resistant to most common household chemicals, especially when properly sealed. However, highly acidic or alkaline cleaners, or prolonged exposure to acidic liquids (e.g., lemon juice, vinegar) can etch or dull the surface, particularly if the sealant is compromised.

Quartz: The non-porous surface makes it resistant to many common household chemicals. However, strong alkaline or acidic cleaners, abrasive cleaners, or harsh chemicals like bleach, paint removers, or oven cleaners can degrade or discolor the resin binder, causing irreversible damage. pH-neutral cleaners are recommended for both.

3.5 Impact Resistance

Granite: Being a very hard, brittle stone, granite can chip or crack under severe impact, especially around edges or sink cutouts.

Quartz: The resin binder provides a degree of flexibility, making quartz slightly more resistant to chipping or cracking from impact compared to granite. However, heavy blows can still cause damage.

3.6 UV Resistance (Outdoor Use)

Granite: As a natural stone, granite is highly UV resistant and can be used in outdoor applications without fear of fading or discoloration from sunlight.

Quartz: The resins used in quartz can be susceptible to UV degradation. Prolonged exposure to direct sunlight can cause the resin to yellow, fade, or discolor over time. Therefore, quartz is generally not recommended for outdoor use or areas with consistent direct sun exposure (e.g., near large, uncovered windows).

4. Maintenance and Longevity

The maintenance protocols significantly differ between the two materials.

4.1 Maintenance Requirements

Granite: Requires periodic sealing. Most granite countertops need to be sealed upon installation and then resealed annually or bi-annually, depending on usage and the granite type's porosity. This process helps maintain its stain resistance. Daily cleaning involves warm water and a mild, pH-neutral cleaner.

Quartz: Is virtually maintenance-free in terms of sealing. Its non-porous nature eliminates the need for sealing. Daily cleaning is simple, requiring only warm water and mild soap or a non-abrasive household cleaner.

4.2 Longevity and Repairability

Granite: With proper care and regular sealing, granite countertops can last a lifetime and even longer. Chips and cracks, while possible, can often be repaired by a professional using epoxy and color-matching techniques. Severe damage might require slab replacement.

Quartz: Also boasts excellent longevity. Its consistent composition means repairs, if needed, can often be less noticeable than with granite, as color matching is easier. However, damage to the resin due to heat is typically irreversible.

5. Aesthetic Versatility and Cost

Beyond performance, visual appeal and budget are key decision factors.

5.1 Aesthetic Range

Granite: Offers unparalleled natural beauty, with unique patterns, swirls, and color variations that are impossible to replicate. Each slab is a one-of-a-kind piece of natural art. This can be a strength (unique look) or a challenge (difficulty in matching seams or achieving uniformity).

Quartz: Provides a much wider and more consistent range of colors and patterns, including solid colors, uniform speckles, and engineered patterns designed to mimic natural stone (like marble or granite) without the natural stone's inherent variations or vulnerabilities. Consistency across slabs makes seam matching easier for large installations.

5.2 Cost

Granite: Prices vary widely based on rarity, origin, color, pattern, and thickness. Entry-level granites can be more affordable than some quartz options, while exotic granites can be significantly more expensive.

Quartz: Generally falls within a mid-to-high price range. While some basic quartz designs might be more expensive than entry-level granites, high-end, complex quartz patterns can rival the cost of exotic granites. The price is often more predictable across batches.

6. Environmental and Health Considerations

The extraction and manufacturing processes also carry environmental and health implications.

6.1 Environmental Impact

Granite: Quarrying granite can have significant local environmental impacts (habitat disruption, dust, noise, water usage). Transportation of heavy natural stone slabs from quarries worldwide contributes to its carbon footprint. However, it is a purely natural material with no chemical binders. Granite is also recyclable as aggregate or for other construction purposes at its end-of-life.

Quartz: The manufacturing process involves high energy consumption for heating, mixing, and curing. The use of petroleum-based resins contributes to its carbon footprint. While quartz utilizes an abundant natural mineral, the manufacturing process makes it an engineered product. Due to the resin content, quartz countertops are generally not recyclable and typically end up in landfills. Some manufacturers are, however, incorporating recycled content into their quartz products.

6.2 Health Considerations

Granite: Historically, concerns about radon emissions from natural stone were raised. However, numerous studies have shown that radon levels from granite countertops are extremely low and insignificant compared to the natural background radon levels found in average homes.

Quartz: As an engineered product, quartz is non-porous and therefore does not harbor bacteria or mold, making it a hygienic choice for food preparation surfaces. The resins used are inert once cured.

7. Application Scenarios and Limitations

Choose Granite when:

You desire a unique, one-of-a-kind natural aesthetic.

You require exceptional heat resistance (e.g., frequent direct placement of hot pans).

You plan for outdoor countertop applications.

You are comfortable with periodic sealing maintenance.

You prefer a truly natural material.

Choose Quartz when:

You desire a consistent color and pattern across large areas or multiple slabs.

You prioritize low maintenance (no sealing required).

You need superior stain resistance and hygiene.

You want a wide array of color options, including solid or unusual patterns.

The countertop will primarily be used indoors away from direct, prolonged sunlight.

Heat protection (trivets) can be consistently implemented.

8. Conclusion: A Decision of Priorities

The technical comparison between quartz and granite reveals that neither material is inherently "better" than the other in all aspects. Instead, the optimal choice hinges entirely on the specific priorities, aesthetic preferences, maintenance willingness, and application requirements of the end-user.

Granite offers the unparalleled beauty and uniqueness of natural stone, coupled with superb heat resistance and durability, but demands consistent sealing to maintain its stain resistance. Quartz, on the other hand, provides consistent aesthetics, superior stain resistance, and minimal maintenance due to its non-porous, engineered nature, but requires vigilance against high heat and is not suitable for outdoor use.

Ultimately, both quartz and granite are premium, durable countertop materials that can significantly enhance the value and functionality of a space. A thorough understanding of their technical characteristics, as detailed in this article, empowers consumers to make a confident and informed decision that aligns perfectly with their lifestyle and design vision.

Name: selena

Mobile:8613176910558

Tel:86-13176910558

Whatsapp:8619323167067

Email:409284553@qq.com

Add:Laizhou ,Shandong , Shandong Province, China