A Technical Breakdown of Costs: Granite vs. Quartz

Granite and quartz are two of the most popular materials for countertops and other surfaces in both residential and commercial applications. While they are often compared for their aesthetic appeal, durability, and maintenance requirements, their cost is a major deciding factor for many projects. To understand which is more expensive, one must go beyond a simple price-per-square-foot comparison and delve into the technical factors that influence the final cost.

The Composition and Sourcing of Materials

The fundamental difference in composition is the primary driver of the price variance between granite and quartz.

Granite: A Natural Stone

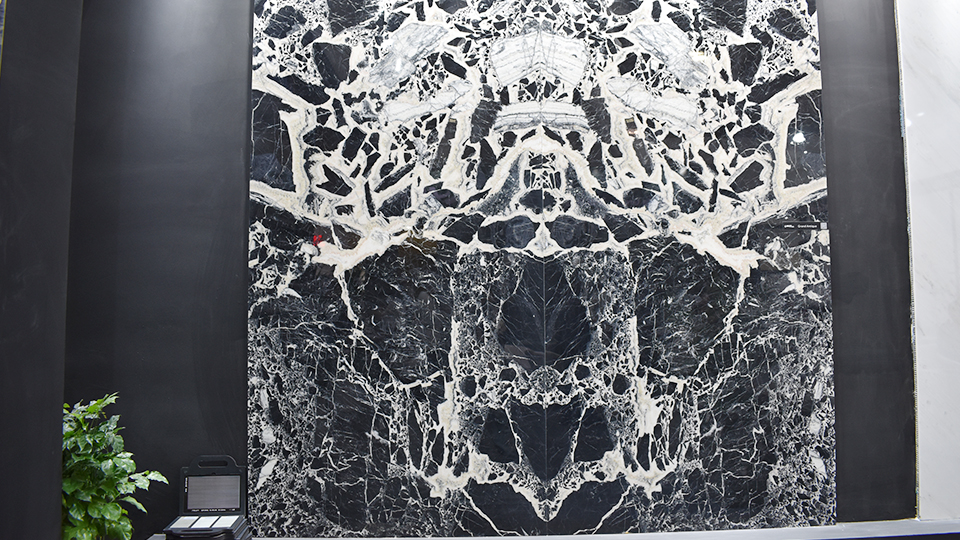

Granite is a 100% natural stone formed from the slow crystallization of magma beneath the Earth's surface. It is quarried directly from the ground in large slabs, which are then cut, polished, and finished for use. Because it's a natural product, each slab of granite is unique, with its own distinct patterns, colors, and veining.

Sourcing Cost: The price of granite is heavily influenced by its origin and rarity. Common granite colors like black, gray, and brown are more readily available and thus, more affordable. However, exotic or rare colors—often with unique patterns and veining—must be quarried from specific locations around the world. The cost of extraction, transportation, and importation of these unique slabs drives their price significantly higher.

Grading: Granite is often sold by grade, which is an unofficial system that reflects the stone's rarity, color, and lack of imperfections. Lower-grade granite may have more visible imperfections or less complex patterns, making it less expensive. Higher grades, on the other hand, are nearly flawless, and their unique patterns and colors command a premium.

Quartz: An Engineered Stone

Quartz countertops are an engineered stone product. They are manufactured by combining approximately 90-95% ground natural quartz with 5-10% polymer resins, pigments, and other materials. The resin acts as a binder, creating a non-porous and durable slab.

Manufacturing Cost: The cost of quartz is tied to its manufacturing process and the brand. The machinery and technology required to produce a high-quality quartz slab with a consistent pattern are expensive. The pigments and resins used also contribute to the final cost.

Pattern and Color: The price of quartz is heavily dependent on the complexity of its design. Basic, solid-color quartz slabs are the most affordable. However, quartz that is engineered to mimic the look of natural stones like marble or granite, with intricate veining and patterns, requires more advanced technology and higher-quality raw materials, making it more expensive.

Brand: Unlike granite, which is a commodity, quartz is a branded product. Brands like Caesarstone, Cambria, and Silestone have proprietary manufacturing processes and offer exclusive designs, which often carry a higher price tag due to their reputation for quality and innovation.

Price Ranges and Factors That Affect Cost

A direct comparison of average price per square foot shows the overlap and general trend.

Granite: The average installed price of granite ranges from $80 to $150 per square foot, but can be as low as $50 for builder-grade options and as high as over $200 for rare, exotic slabs.

Quartz: The average installed price of quartz ranges from $50 to $200 per square foot, with a wider spread between budget-friendly and high-end options.

Beyond the cost of the raw material, several other factors contribute to the total project price. These factors apply to both granite and quartz but can impact their final price differently.

1. Fabrication and Installation

This is one of the most significant line items in the total cost. Both granite and quartz require professional fabrication and installation.

Granite: Because of its natural origin, a granite slab may have minor imperfections or structural weaknesses that require an experienced fabricator to work around. The weight of the stone also makes it challenging to transport and install, often requiring multiple laborers.

Quartz: The consistency of engineered quartz can make it slightly easier to cut and work with. However, the installation still requires a professional with specialized tools to ensure proper fitting and seamless joints, especially for large, complex layouts.

2. Edge Profiles and Finishes

The complexity of the edge profile you choose can significantly impact the cost.

Granite: Simple edge profiles like an "eased" or "straight" edge are standard and often included in the base price. More intricate designs like an ogee or bullnose require more labor and specialized tooling, adding to the cost.

Quartz: Similar to granite, complex edges will increase the price. However, the uniform composition of quartz can sometimes make it easier to achieve a clean, polished edge compared to granite, which may have varying mineral densities.

3. Project Complexity

The layout of the project itself plays a major role in the final price.

Cutouts: Both materials require cutouts for sinks, faucets, and cooktops. The number and complexity of these cutouts will increase the fabrication cost.

Seams: Larger countertops may require a seam where two slabs meet. While a professional can make a seam nearly invisible, the process requires precision and time, which is reflected in the labor cost.

The Long-Term Cost: Maintenance and Durability

The initial purchase price isn't the only financial consideration. The long-term costs associated with maintenance and durability can affect the total cost of ownership over the lifespan of the countertop.

Granite Maintenance: Granite is a porous natural stone. This means it is susceptible to staining from liquids like wine or oil if left on the surface for too long. To prevent this, granite countertops require periodic sealing, typically once every 1-3 years. The cost of a professional sealing service is an ongoing expense, and neglecting it can lead to permanent damage and a much larger repair bill.

Quartz Maintenance: Quartz is non-porous due to the resin binders used in its manufacturing. This makes it highly resistant to stains, and it never needs to be sealed. It requires very little maintenance, usually just a simple wipe-down with soap and water. This lack of ongoing maintenance can make quartz a more cost-effective choice in the long run.

Conclusion: The Final Verdict

So, which is more expensive? For entry-level and mid-range options, granite is typically more affordable than its quartz counterpart. The cost of a common granite slab, combined with basic fabrication, often comes in lower than a similarly styled quartz slab.

However, once you move into the high-end, exotic category, the costs begin to overlap and can even invert. A rare, uniquely patterned granite slab can easily cost more than a high-end quartz design. Conversely, the most intricate and exclusive quartz designs from top brands can surpass the cost of many granites.

Ultimately, the choice comes down to a balance of initial cost, long-term maintenance, and personal preference. If you're looking for a budget-friendly option and don't mind the minimal maintenance of sealing, granite is likely the more affordable choice. If you prioritize a unique, consistent pattern, or value the low-maintenance, non-porous nature of a countertop, quartz may be the better investment despite its potentially higher upfront cost.

Name: selena

Mobile:8613176910558

Tel:86-13176910558

Whatsapp:8619323167067

Email:409284553@qq.com

Add:Laizhou ,Shandong , Shandong Province, China